RDO Springs - 10 Rue Benjamin Delessert - 60510 BRESLES - FRANCE

RDO Springs - 10 Rue Benjamin Delessert - 60510 BRESLES - FRANCE

Guide Ressorts de compression - Ressort de compression

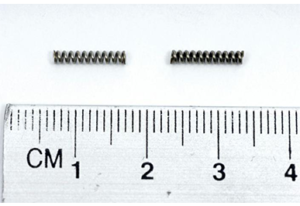

COMPRESSION SPRING

The CETIM (Centre Technique des Industries Mécaniques) published in December 2019, a “guide for designers, users and manufacturers”, which concerns THE COMPRESSION SPRINGS.

This very complete 50-page document explains all the constraints that are submitted to manufacturers for the realization of parts. We will indicate here the main chapters of this document in order to better understand the essence of this document.

The first part recalls the distinction between coiled compression springs :

The first part recalls the distinction between coiled compression springs :

- Hot: the steel compression spring is “forged” and then shaped. It undergoes quenching and tempering to maintain the characteristics of the spring.

Cold: the steel compression spring is cold-formed, and does not undergo any treatment after manufacture other than stabilization in furnaces to preserve its characteristics.as well as the different existing standards for cold wound compression springs for standard features (wire diameter <= 16mm, free length <= 1000 mm, average diameter <= 200 mm …) :

- NF EN 13906 -1 : European Standard “Cylindrical helical springs made from round wires and bars – Calculation and design – Part 1: Compression springs“.

- NF EN 15800 : European Standard “Cylindrical helical springs made of round wire – Quality requirements for cold-formed compression springs“.

The second part, (page 14), explains all the characteristics of compression springs defined in standard NF EN 13906.

Each chapter of the list below is commented and associated tables will help you better understand the requirements.

- Environmental requirements (type of material, working temperature, etc.))

- Desired space requirement (including functional play)

- Operating range (generally between 30 and 70% of its maximum deflection)

- Choice of the diameter (which will influence the requested load)

- Calculation of shear stress load(E1), number of useful coils(E2), spring stiffness, deflection under load (S)

- Cohesion and verification of these calculated constraints

- Tolerances (according to EN 15800) on diameter, load, perpendicularity and parallelism of ground springs

- As well as a guide for the establishment of a standard plan and the drafting of the main coasts that will be included in it.

The third part (page25) deals with the manufacturing process of compression springs.

- Preparation and preservation of the raw material

- Winding direction of the compression spring (which will influence the overall geometry)

- Heat treatment to be considered (depending on the steel grade) for stabilization and “stress relieving” (relaxation of residual stresses)

- The pre-conformation (initial load on the spring to bring it to better respond to the stresses – the so-called blocking operation).

- Grinding of the ends (which will be necessary in case of a flat bearing surface)

- Surface treatment (shot blasting, tribofinishing, passivation …)

The fourth part (page 29) explains the inspection operations to be carried out and the instruments recommended for the characteristics of the compression springs produced.

- Outside and inside diameters (Calipers, bushings, pins)

- Lengths and loads: free length without load, or block length under load, with tare machines

- Perpendicularity (Squares, profile projector or optical measurement)

- Visual checks (winding direction, chamfering, grinding)

- Fatigue tests, chemical tests

- Material used (material certificate to be provided according to NF EN 10204)

Finally, this document recommends for the realization of these parts :

- An adapted quality approach, with SPC and FMECA controls, respect for traceability, controlled machine and process capabilities, verified and calibrated control, measuring and testing equipment…

- To work in PPM (number of good or bad parts per million parts produced)

- Make sure you have reliable sources for the raw material which can contain various defects if not controlled: inclusions, roughness, scratches, manufacturing heterogeneity, drawing chemicals, winding defects ….

At the end of the document, various documentary appendices in the form of a table will help you to choose :

- The raw material to be used or prescribed for your compression spring,

- The surface treatment to be requested according to your expectations of resistance,

- Ruler for shot blasting,

- Recommendations for packaging and transport.

RDO SPRINGS respects all the recommendations of this guide.

and proves it via :

- ISO 9001 and EN 9100 certifications renewed

- Its frequent customer audits of very demanding sectors such as the medical (pharmaceutical, medical, cosmetics), aeronautics and space sectors.

- His active participation in the training school for trimmers (AFPIDEM)

- Its active presence at the UNM : (Union de Normalisation de la Mécanique )

- Its active representation in the French ressortiers union (FIM ressorts – Fédération des Industries Mécaniques)

We strongly advise you to consulter this document because it reminds many rules and information about for the designer, the manufacturer and the user. You can obtain it directly by clicking on the image above from CETIM (if you are affiliated with this organization) or order it from them:

- You can order the standards on the AFNOR (Agence française de normalisation) website:

- https://www.boutique.afnor.org/recherche/resultats/mot/13906

- https://www.boutique.afnor.org/recherche/resultats/mot/15800.

(+33) 3 44 07 34 34

(+33) 3 44 07 34 34 contact@rdosprings.com

contact@rdosprings.com

REQUEST FOR QUOTATION

REQUEST FOR QUOTATION download the brochure

download the brochure