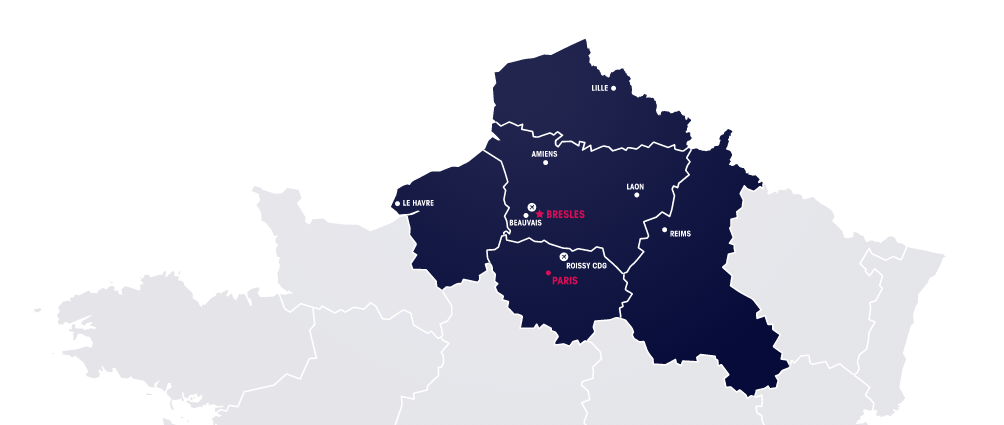

RDO Springs - 10 Rue Benjamin Delessert - 60510 BRESLES - FRANCE

RDO Springs - 10 Rue Benjamin Delessert - 60510 BRESLES - FRANCE

Wave Springs | RDO Springs French spring specialist

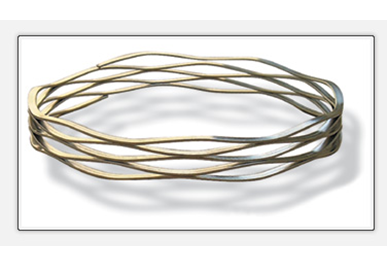

DEFINITION :

Wave springs are the result of recent spring technology.

The wire used doesn’t look round, it looks flat. These are frequently wires that have been rolled (crushed by successive passes) to obtain a wire of the desired thickness.

This wire is then worked to give it similar characteristics to compression springs with the advantage of much higher loads.

The wave spring can resist the same forces as a round wire spring but with a much shorter stroke and a smaller footprint.

The support of the coils one on top of the other gives it unique characteristics for many highly technical applications.

This spring is also called a sine spring.

MANUFACTURING PROCESS :

- Small run (<1000 parts),

- Production is subject to several very precise phases,

- RDO Springs primarily produces these springs for industry sectors where very high precision and technicality are required.

CALCULATIONS – PLANS – TECHNICAL QUOTATION :

Due to the manufacturing complexity, this spring is produced to plan.

The wire to be used must be analyzed in a precise technical study in order to satisfy our customers’ expectations. We help you define these plans.

Numerous useful aspects are required to manufacture it, including wire and inner diameters, winding directions, axial loads to be taken up/released and the different effective lengths (unrestricted height, loaded height).

Once the plan is completed and transmitted, our engineering and design department checks the dimensions and calls you back if necessary. Tests are then conducted to verify that the requested characteristics can be validated on initial samples.

EQUIPMENT :

RDO Springs has :

- Several machines used to roll the wires and manufacture these specific wave springs,

- Several recent software programs to calculate dimensions and static and dynamic loads on springs,

- All the necessary control instruments to check the required dimensions (shadowgraph, measurements taken via imaging, 2D LED, 3D LED, etc.)

FINAL TREATMENT OF THE MANUFACTURED SPRING :

Several million combinations are possible depending on the mechanical characteristics required on the dimensions or the resistances.

To ensure that a spring meets your requirements over time, heat treatments (ovens) are performed. Chemical treatments can also be performed (tribofinishing or passivation) in order to guarantee these characteristics over time.

RDO Springs has two modern production lines for these operations.

Subcontracting operations (painting, cataphoresis and chemical treatments) can be performed by a subcontractor located near our manufacturing facility.

MATERIALS PROCESSED :

RDO Springs uses many types of materials for its manufacturing (see list below). For wave springs, these products can’t necessarily all be rolled. Please contact our technical services for in-depth studies on the product you would like to use

- SM, SH, DH, etc. spring steel

- Oteva©, Stato© and becrosi© Chrome silicon

- Stainless steel 1.4310, 1.4310 HS, 1.4401, 1.4568, 1.4462

- Galvanized SM, galvanized SH, Bezinal© SM pre-coated steel,

Bezinal© SH

- Inox doux 1.4301 • Inox implantable 1.4441

- Inconel 600, 625, 718, 750 • Monel, Nimonic, Uranus, Titanium, etc.

- Phosphor bronze, beryllium, copper, brass • square section, rectangular section

OUR RECOMMENDATIONS :

The manufacture of wave springs is based on several international standards that define tolerances and the standard manufacturing process.

RDO Springs is certified ISO 9001 (Quality) and EN 9100 (Quality ++: Aerospace and Defense sectors) proving its considerable expertise in this field.

There are no so-called “standard” springs. Each spring is specific and requires an appropriate approach so we can meet your requirements

RDO Springs

10 RUE BENJAMIN DELESSERT

60510 BRESLES

contact@rdosprings.com

www.rdosprings.com

(+33) 3 44 07 34 34

(+33) 3 44 07 34 34 contact@rdosprings.com

contact@rdosprings.com

REQUEST FOR QUOTATION

REQUEST FOR QUOTATION download the brochure

download the brochure