RDO Springs - 10 Rue Benjamin Delessert - 60510 BRESLES - FRANCE

RDO Springs - 10 Rue Benjamin Delessert - 60510 BRESLES - FRANCE

Electro-Erosion | RDO Springs spring specialist

DEFINITION :

Electro-erosion is an electrical process that allows us to cut parts with very high precision, without generating burrs.

This process, called EDM (Electrical Discharge Machining), is a process associated with machining that involves removing material from a conductive sheet metal part on the periphery, but also in the center of the part.

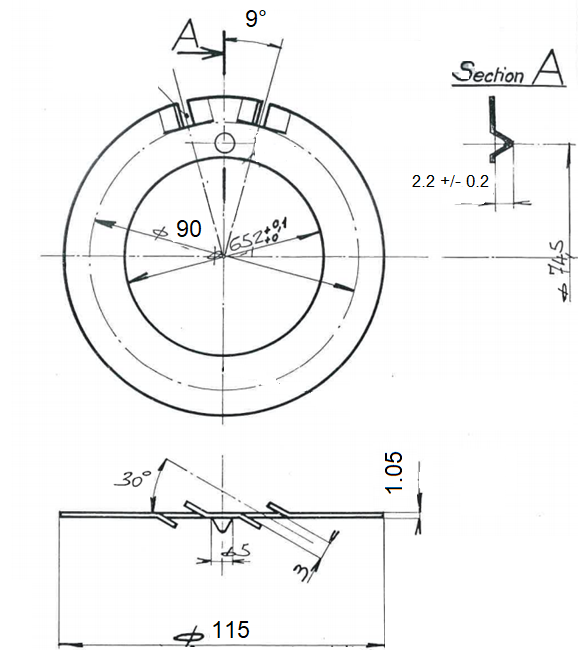

The diameter of the cutting wire is very small, so very precise cuts can be made (see example below).

Example: Sheet steel was cut by electro-erosion to form a round part on almost the entire circumference and perforated in the center. This part was then worked on the periphery to lift the small pre-cut lugs on either side, generating a spring effect on the periphery of the part.

MANUFACTURING PROCESS :

- Small run (<500 parts),

- Production is subject to major preliminary phases in order to obtain the final technical quality on the product desired by our customers.

CALCULATIONS – PLANS – TECHNICAL QUOTATION :

These products are produced to plan.

It is also important to know how these products will be used in order to take into account their context of use.

Numerous useful aspects are required to manufacture them, which implies obtaining a well-dimensioned plan that sets out your specific requirements.

Our engineering and design department will be able to answer your requests because we have considerable expertise in this area.

EQUIPMENT :

RDO Springs has :

- Several machines that can produce these specific and complex parts

- Several recent software programs to calculate dimensions and static and dynamic loads on springs

- All the necessary control instruments to check the required dimensions (shadowgraph, measurements taken via imaging, 2D LED, 3D LED, etc.)

FINAL TREATMENT OF THE MANUFACTURED SPRING :

To ensure that a spring meets your requirements over time, heat treatments (in ovens) are performed. Chemical treatments can also be performed (tribofinishing or passivation) in order to guarantee these characteristics over time.

RDO Springs has two modern production lines for these operations.

Subcontracting operations (painting, cataphoresis and chemical treatments) can be performed by a subcontractor located near our manufacturing facility.

MATERIALS PROCESSED :

- SM, SH, DH, etc. spring steel

- Oteva©, Stato© and becrosi© Chrome silicon

- Stainless steel 1.4310, 1.4310 HS, 1.4401, 1.4568, 1.4462

- Mild stainless steel 1.4301 – Implantable stainless steel 1.4441

- Inconel 600, 625, 718, 750 • Monel, Nimonic, Uranus, Titanium, etc.

- Phosphor bronze, beryllium, copper, brass • square section, rectangular section

- Galvanized SM, galvanized SH, Bezinal© SM pre-coated steel,

Bezinal© SH

OUR RECOMMENDATIONS :

The manufacture of electro-erosion springs is based on several international standards that define tolerances and the standard manufacturing process.

RDO Springs is certified ISO 9001 (Quality) and EN 9100 (Quality ++: Aerospace and Defense sectors) proving its considerable expertise in this field.

There are no so-called “standard” springs. Each spring is specific and requires an appropriate approach so we can meet your requirements

RDO Springs

10 RUE BENJAMIN DELESSERT

60510 BRESLES

contact@rdosprings.com

www.rdosprings.com

(+33) 3 44 07 34 34

(+33) 3 44 07 34 34 contact@rdosprings.com

contact@rdosprings.com

REQUEST FOR QUOTATION

REQUEST FOR QUOTATION download the brochure

download the brochure