RDO Springs - 10 Rue Benjamin Delessert - 60510 BRESLES - FRANCE

RDO Springs - 10 Rue Benjamin Delessert - 60510 BRESLES - FRANCE

RDO SPRINGS - Ressorts de haute technicité

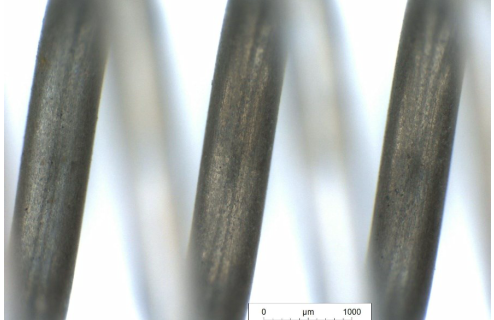

RDO SPRINGS manufactures springs for different sectors of activity with very high dimensional requirements, resistance to loads or resistance to aggressive environments.

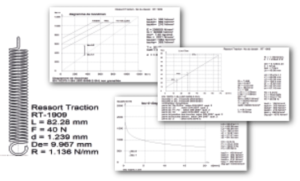

The validation files are complex, generate high-level technical exchanges and numerous tests are carried out in order to validate the plans and processes defined.

EN 9100 quality certification is a requirement for the majority of these sectors.

Specific materials are used to achieve compliance with customer requirements.

Major sector examples :

DEFENSE : springs for manufacturers delivering DASSAULT AVIATION fighter planes (MIRAGE-RAFALE), helicopters, ground armament (tanks and assault vehicles, missiles) or nautical (submarines)

AERONAUTICS : transport aircraft (AIRBUS), transport helicopters

AEROSPATIAL : springs for OEMs delivering parts for ARIANE rocket, VEGA rockets (small size rockets), satellite engine parts

MEDICAL : compression springs for companies that will manufacture pumps and valves for sprays or atomizers (absolute cleanliness of the parts – high accuracy of dosages), precision equipment for bone surgery, blood catheters, ophthalmological probes, artificial respirators

NUCLEAR : springs for regulation and pressure systems

ROBOTICS : parts of industrial robots, control robots

ADVANCED INDUSTRIES : traction springs for machines with very high work rates (e.g. weaving looms with fatigue and stress tests)

Main references of these high-tech springs:

ARESIA (ALKAN) – APTAR – ARIANE GROUP – ALSYMEX (ATMOSTAT) – CEA – COUSIN BIOTECH – EATON – EMERSON – JABIL – JPB SYSTEM – JOHN CRANE – LABLABO – LATTY – MILTON ROY – NAVAL GROUP – NEMERA – VYGON (PEROUSE MEDICAL) – RENK – ROBOCATH – SAFRAN – STAUBLI – SYMATHESE …

Takeoff of the Ariane5 ECA launcher, flight 247 on February 5, 2019 from the Guiana Space Center (photo Ariane space).

(+33) 3 44 07 34 34

(+33) 3 44 07 34 34 contact@rdosprings.com

contact@rdosprings.com

REQUEST FOR QUOTATION

REQUEST FOR QUOTATION download the brochure

download the brochure